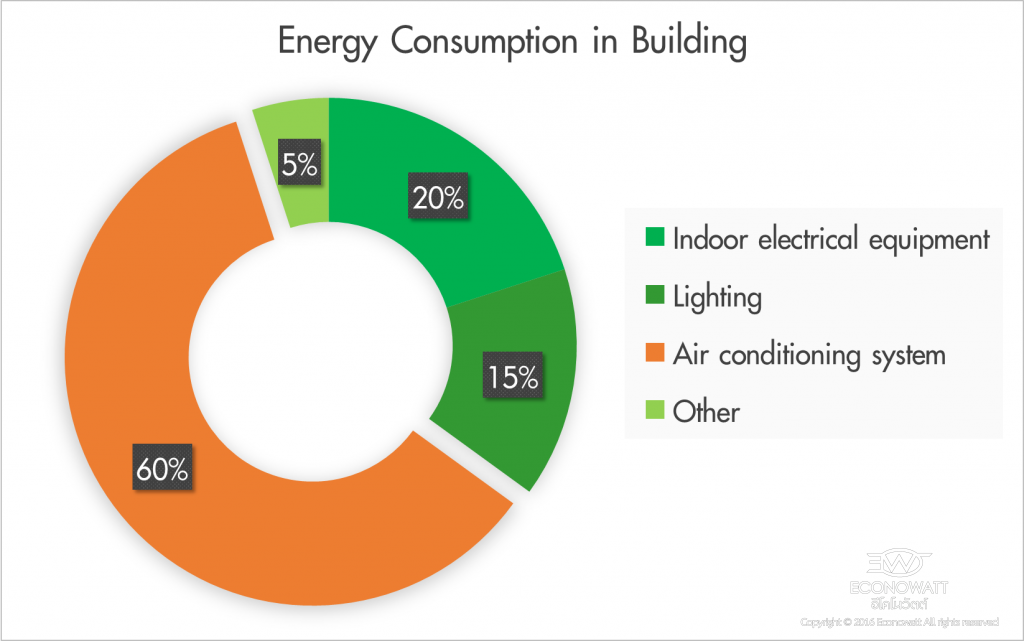

Energy Consumption in Building

Generally energy consumption in large commercial buildings, shopping malls, hospitals, hotels, and the factory can be divided into 4 mains proportion which are

- Indoor electrical equipment

- Lighting

- Air conditioning system

- Other

The air conditioning system consumes the largest energy portion and consequently the commercial buildings will use the most efficient water cooled central air conditioning system. The central air conditioning system requires cooling towers for cooling down the condenser water.

The cooling towers reduce condenser water temperature by reject waste heat to the atmosphere and return low temperature water to the condenser. When the condenser water exchanges heat in water with outside air, which will bring dust and fine particles that contain germs and microorganisms into the condenser water. Causing sediment, biofilms in tray and tube of the cooling tower.

The growth of biofilms will promote micro-bio fouling that causes corrosion and scale building up at the inside condenser pipe wall. At the condenser pipe, the thickness of scale will prevent heat dissipate to the condenser water. Overall cooling system performance will reduce dramatically since the condenser pump required more energy than its usual and heat cannot be rejected from the system.

Lichen, Slime and Biofilm in Cooling Tower

Corrosion and Scale Build Up

ECONOWATT have long seen these problems and invented an ozone unit for condenser water treatment without residual chemicals. The ozone unit can be absolutely able to control the increasing of scale inside the condenser tube. It has been tested since 2008 at Energy Conservation Building in Honour of His Majesty the King, Department of Alternative Energy Development and Efficiency, Ministry of Energy.

ECONOWATT OZONE WATER SYSTEM

ECONOWATT high-efficiency ozone water system prevents biofilms which cause scale deposits in the condenser tubes. Not only decomposing and falling off the scale but also prevent scale formation in all pipelines. Resulting in energy savings in electricity costs caused by blockage of condenser pipes in all water chiller units. Moreover, ECONOWATT’s ozone water system is also recognized as an environmentally friendly product and perfectly protects against harmful germs for health. It can cancel all chemicals use and the softener water system. Besides, it can use tap water to make up water directly into the cooling tower and disinfect Legionella in the cooling tower, which is the cause of Legionnaires’ disease, lung inflammation in the respiratory system.

Compairing Cooling Tower Treatment Between Conventional System and ECONOWATT Ozone Water System

ECONOWATT ozone water system is considered an innovative product. It has been registered in the Thai Innovation Accounts by the Bureau of Budget. Which has a disinfecting ability more than 3,000 times more than chlorine. Our unique pump which has ozone mixing efficiency up to 80%. Saving electricity from conventional ozone systems up to 33%. Compact size at 2.8 times lower in size, 50% lower in weight, and easy install with reduced 90% of labor cost and piping line compared with a conventional ozone system. Our ozone water system with a 4G online monitoring system in which customers can see real-time the operation of the machine status on mobile phones online for 24 hours, whether the system is operating normally or has stopped working or not.

In conclusion, generally, ECONOWATT provides full time energy saving guarantee for water cooled chiller by monitoring air conditioning system performance via condenser approach temperature

ECONOWATT ELECTRO HARDNESS REMOVAL

In addition to the ECONOWATT ozone water system, ECONOWATT has collaborated with MTEC and invented EHR (Electro Hardness Removal) without chemical usage. EHR has an outstanding property in absorbing minerals in high-temperature water. Which is suitable for water with high calcium and magnesium. EHR is using the principle of electrolysis by supply current to a metal plate (Anode) to make the reaction. The hardness in the form of Ca2 + Mg2 + is sucked to form crystals on the cathode side, which can easily clean the cathode plate with brittle slag crystals by scraping off. EHR is suitable for cooling tower systems, effluent water with high TDS (Total Dissolved Solids) exceeding the standard, and high hardness recycled water. In the cooling water system, it can increase the cycle of concentration more than 10 times than usual. Moreover, the decrease of calcium and magnesium can prevent the formation of scale in the pipeline to meet LEED (Leadership in Energy and Environmental Design) standards.

OUR CLIENTS

PROFESSIONAL SOLUTIONS

ECONOWATT is expert in enegy conservation, water and air treatment solutions. If you are interested in knowing more about our solutions, we are welcome to serve with your problems.