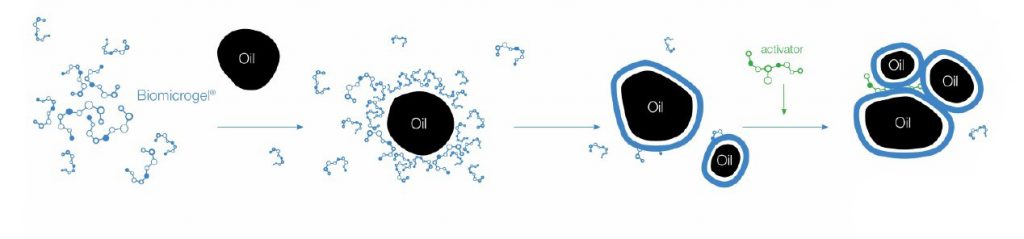

By using natural innovative nanotechnology that able to extract and separate oils from emulsions. This water in oil emulsion is in the form of liquids derived from petroleum, vegetable oil, etc. This natural innovative nanotechnology using organic extracts of cellulose from the apple peel and sugar beet pomace are collectively called BIOMICROGEL®. It has the property to reduce the surface tension of liquid emulsion. BIOMICROGEL® has a high affinity for the phase interface between oil and sludge water. Therefore, when the BIOMICROGEL® solution is added to the emulsion, the BIOMICROGEL® particles displace all suspension solid from the surface of the oil droplets. BIOMICROGEL® is effectively separate stable water-oil emulsion with faster reaction and sediment formation time even though the concentration of oil mix in water less than 0.1 mg / l.

Nowadays, vegetable oil factories such as palm oil and coconut oil use compression principles in the oil production process. Which still has a large amount of oil remaining from the production mixed in the waste. Using BIOMICROGEL® will improve the efficiency of oil capture in the production process. Resulting in increased production capacity in palm oil and coconut oil factories without affecting the structure of the oil products. Since BIOMICROGEL® is a 100% biodegradable material. By-products not only reducing oil loss from production but also decreasing the amount of oil-contaminated wastewater from production.

Before and after BIOMICROGEL® react with the emulsion.

PROFESSIONAL SOLUTIONS

ECONOWATT is expert in enegy conservation, water and air treatment solutions. If you are interested in knowing more about our solutions, we are welcome to serve with your problems.